Expert Hardening, Beyond Steel

PRIKNER heat treatment shop

INDUSTRY EXPERTS

SINCE 1990

#quenching #hardening #heat treatment of metals #capillary soldering #annealing

#metallography #heat treatment shop #carburizing #surface blasting

IMPROVING YOUR METALS

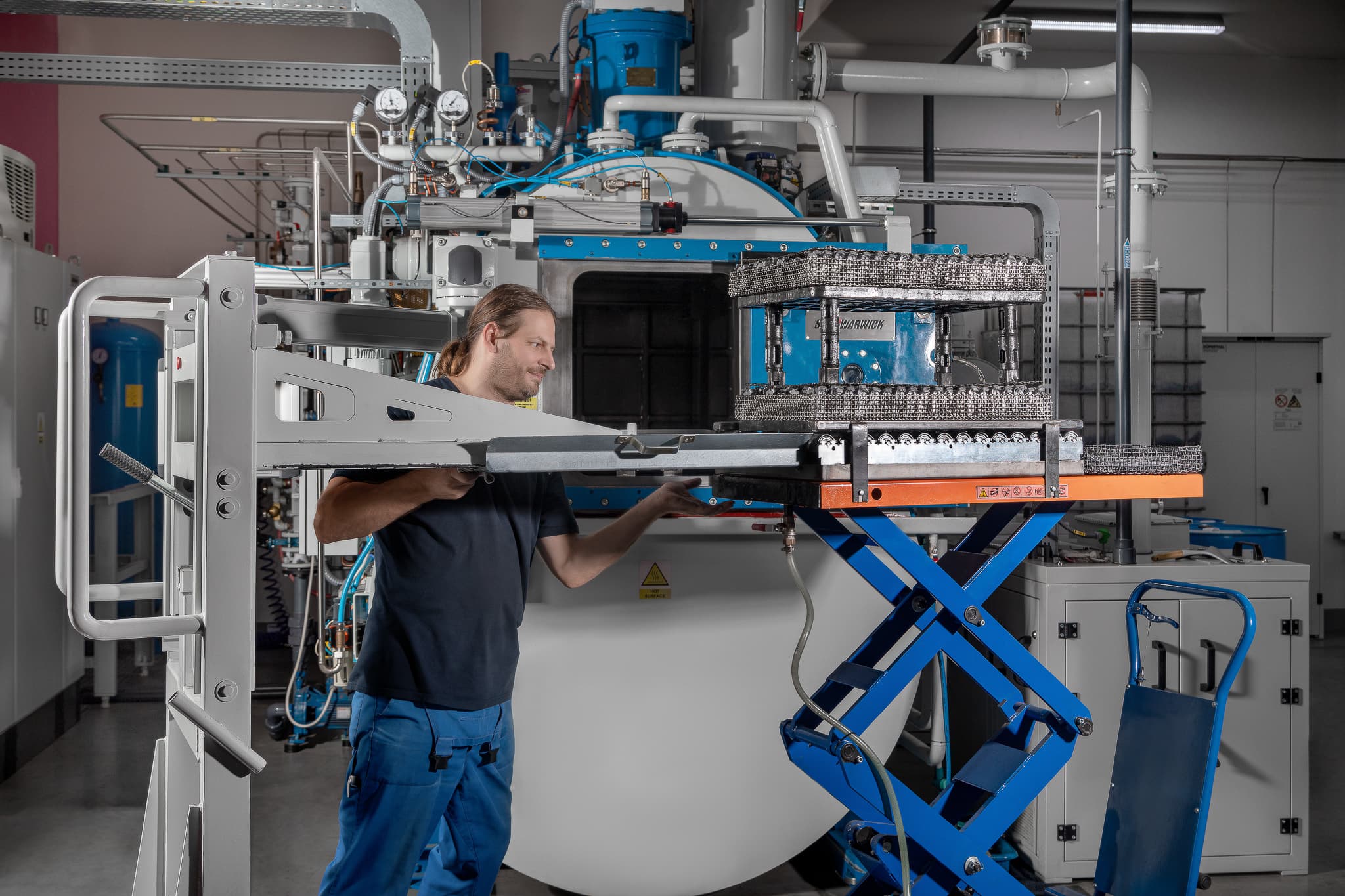

Welcome to the heat treatment shop, where a blend of expertise and passion has been shaping metal since 1990. While much has changed since our founding under the name Otakar PRIKNER, our commitment to delivering top-quality services remains unwavering. Our service portfolio spans a broad spectrum of processes, from hardening and carburizing to nitriding, annealing, metallography, and hardness testing. We continually refine and enhance these techniques for the benefit of both our clients and the environment. No job is too small for us; we stand ready to tailor our services to the unique needs and preferences of all, including small and medium-sized enterprises.

Every day for over 30 years, our proficiency in the realm of metal heat treatment has propelled our clients' businesses forward. Let us extend our assistance to you as well. Join us in our pursuit of excellence.

THE TECHNOLOGIEs IN WHICH WE EXCEL

since 1990

metal hardening

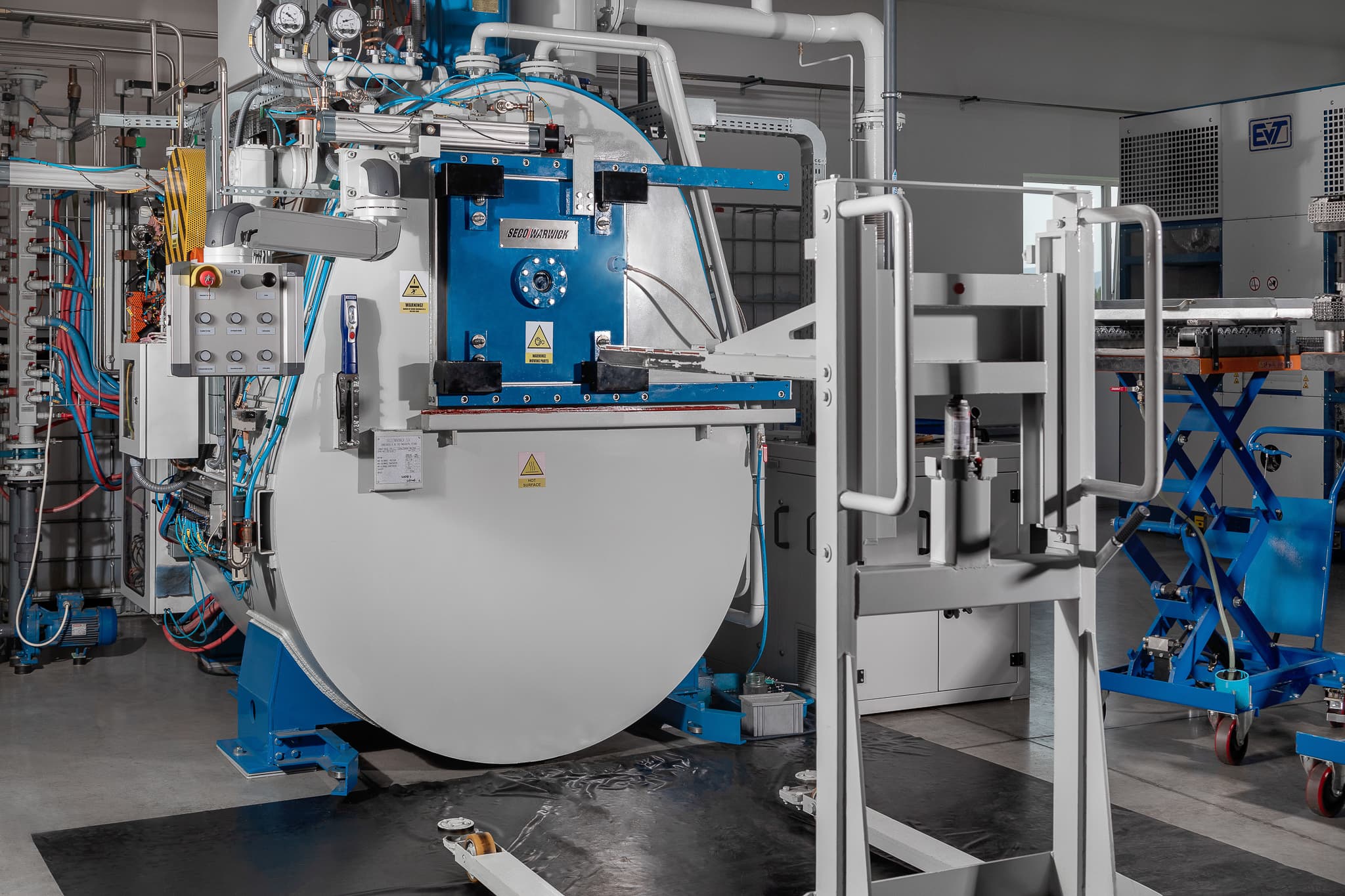

Hardening is a type of heat treatment that involves heating the material to the quenching temperature, followed by tempering, and finally cooling at a supercritical rate. It is used to enhance the mechanical and physical properties of the material, particularly its hardness and wear resistance. In PRIKNER heat treatment shop, we perform steel hardening in a protective atmosphere using salt bath quenching, bainitic hardening, as well as vacuum oil or nitrogen overpressure quenching.

ANNEALING

Annealing involves controlled heating of the metal to the annealing temperature, followed by holding and slow cooling to room temperature. It allows for the reduction of internal stresses in the material, improves its ductility, reduces hardness, and thus facilitates machining. In PRIKNER heat treatment shop, we carry out soft annealing, normalizing, stress relieving annealing, spheroidizing annealing, isothermal annealing, solution annealing, homogenization annealing, recrystallization annealing, and annealing for magnetic properties.

Capillary vacuum soldering

Capillary vacuum soldering is a process used to join metal parts with significantly different weights or composed of different materials that are impossible to join using conventional methods. The resulting joints are mechanically strong, clean, and vacuum-tight, with individual parts remaining undeformed. This technique finds primary application in electrical engineering, but it is also utilized in general engineering. In PRIKNER heat treatment shop, we solder steels of nearly all grades.

CHEMICAL HEAT TREATMENT OF METALS

Chemical heat treatment of metals involves processes that combine chemical reactions with thermal operations. Their aim is to modify the structure and achieve the desired properties of the material, primarily increasing hardness, toughness, and wear resistance. PRIKNER heat treatment shop offers carburizing and carbonitriding in gas with salt bath quenching, low pressure carburizing in vacuum furnaces with oil quenching or nitrogen overpressure, vacuum nitrocarburizing with oil quenching, post-carburizing freezing, nitriding and nitrocarburizing in gas, and oxidation after nitriding or nitrocarburizing.

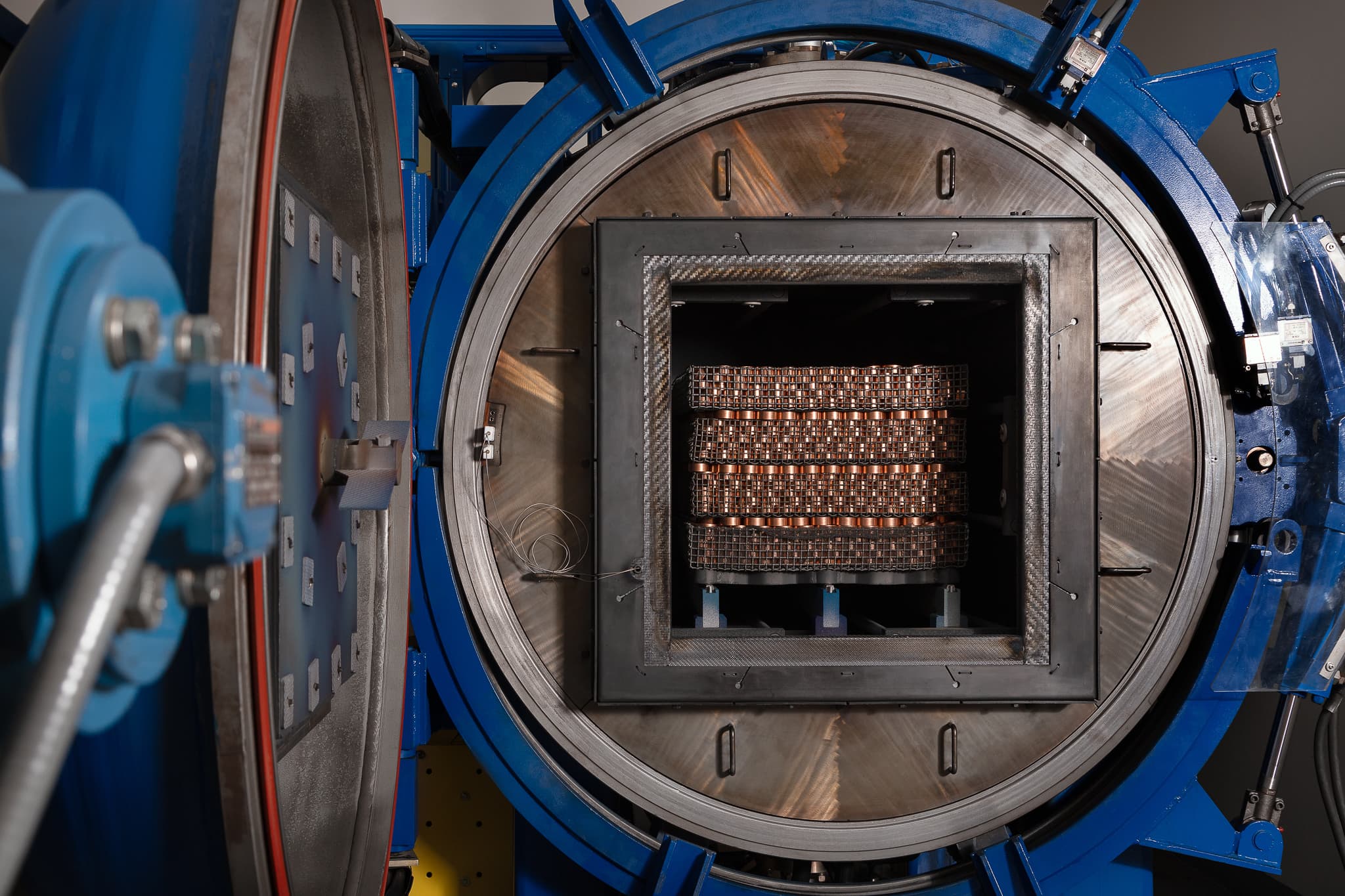

non-ferrous metals and alloys processing

Processing of non-ferrous metals and alloys encompasses selected processes aimed at achieving an optimal structure and mechanical, thermal, and electro-physical properties of the material. It is crucial in the manufacture of a wide range of products from electronic components to structural materials. In PRIKNER heat treatment shop, we anneal copper and brass and harden aluminum, bronzes, and other non-ferrous alloys.

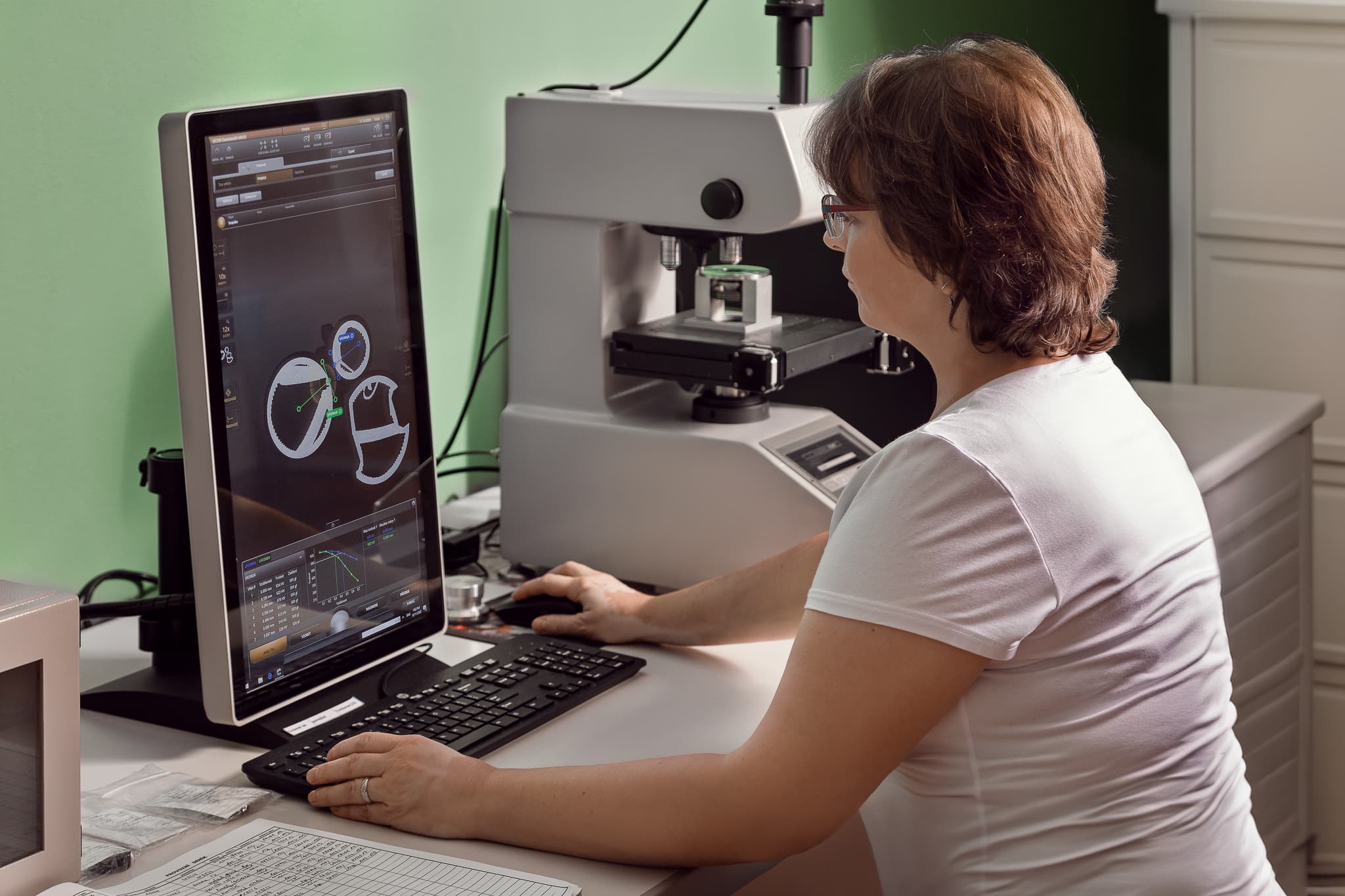

Metallography

Metallography is an important tool for assessing the structure of materials at the microscopic level. It allows for the evaluation of the quality of metal heat treatment and identification of potential defects that could affect the final material properties. In PRIKNER heat treatment shop, we offer hardness testing of metals, layer thickness measurement, spectral analysis, chemical composition analysis, and optical metallography.

blasting

Blasting is a method of mechanical surface treatment of metal, cast iron or alloy products. During surface blasting, the material is exposed to a carefully controlled stream of abrasive particles. This cleans it of scale, rust and impurities. Blasting is carried out before or after heat treatment or as a base for subsequent electroplating operations. In PRIKNER heat treatment shop, we blast using cast iron grit or glass beads.

WHY PRIKNER HEAT TREATMENT SHOP

IS THE BEST PARTNER FOR YOU